If you’re looking for an effective Equipment Condition Report to use for your business, you’ve come to the right place. But if you want to really speed up your team’s inspection processes, then check out what we’ve got in store in this accompanying article.

Using an Equipment Condition Report is key to maintaining control of a fleet, or even fixed equipment on your client sites or your own properties. Equipment inspection can include vehicles, fixed equipment (like a leased generator, or an HVAC system your company might be maintaining), you could even use a report like this for office equipment like printers or fax machines.

The point is that everywhere you look in today’s world, you’re going to find equipment doing something, and those of us like you have to manage it. What better way than to adopt an organized system of equipment condition reporting to keep your equipment management processes under control.

In this article, we’ll provide some insights about best practices for your equipment inspections, be it on-site or off-site. We’ll also discuss some helpful tips to aid your organization in streamlining the process of equipment inspection so you can lower your costs, be more efficient, and claim all the glory, so stick with us.

Table of Contents

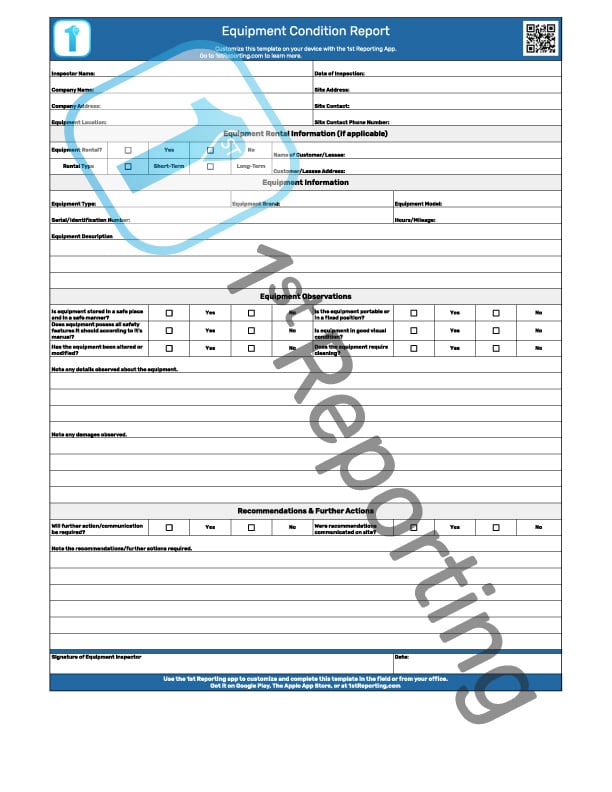

The Equipment Condition Report has several sections, conveniently separated for your team’s convenience. Here’s a brief description of each that you can use to help train your team on the new template:

The administrative section of the Equipment Condition Report includes several critical pieces of information including the name of the team member performing the inspection, the company name, and address, and the date of the inspection.

Also included in this section is an area to include the site address, contact name, and number. These further critical pieces of data allow you to get a quick snapshot when reviewing equipment inspection reports – right at the top of the document – nice, clearly marked text boxes for fast skimming.

Whether your company is the renter or the rentee, this section of the Equipment Condition Report includes the rental information pertinent to the equipment information disclosed on the report.

The basic information regarding the would-be inspected equipment finds a home in the Equipment Information section of the Equipment Condition Report. You can instruct your team to include the equipment type, brand, model, serial number, hours/mileage, and even a description.

The functionality of this template shines through here where you can see that you can easily adapt this template for nearly any type of equipment you may need to inspect. So, whether you’re operating in the construction, utilities, health care, even service providers and rental companies will find this template useful. But we’ll get into the other benefits you can get when using tools like checklists, audit forms, and inspection templates for your equipment and other types of inspections.

When performing an equipment inspection at a remote site, or even at your home base facility, it’s vital to note all the conditions of the equipment. This section of the Equipment Condition Report allows you to do just that.

Far beyond what you might find for a basic equipment inspection report, our Equipment Condition Report is set up to help you with your team’s observational data capture. By encouraging including information about the way the equipment is stored, the cleanliness of the equipment, and two full sections for detailing those observations, you will find team members create far more concise and specific equipment inspection reports.

The last real data input and observation capture section of the Equipment Condition Report consists of an area to record equipment management recommendations and also further actions required.

We’ve done our best to set this template up for you to use on multiple types of equipment, from mobile, even automotive forms of equipment to fixed equipment systems. And you know as well as we do that at even the simplest company there are likely multiple pieces of equipment.

So, ensuring that you capture those recommendations and required actions communicated by your team members performing the equipment inspections is critical to your success with your equipment management.

Lastly, like any other professional inspection form or template, we’ve included a section for your inspection team member to sign off on the document’s accurate completion.

How To Use The Equipment Condition Report

Using the Equipment Condition Report is simple. Merely download, print, and distribute to your team members.

However, in a world of environmental challenges, and rising operating costs, it’s wise to utilize printing the template a minimum number of times. We recommend projecting the number of equipment report inspections for the week, and print an appropriate number of sheets.

Similarly to projecting the week’s inspection outcomes, it is wise to pre-train staff on the use of the Equipment Condition Report. Pre-training before they use the form in the field will allow them time to develop a familiarity with the document. And when familiar, the team members will be much less likely to make mistakes.

Given a finite number of copies, team members will also be compelled to write neat and efficient reports. And you might just save on expensive paper and ink as well.

Since we were just discussing efficiency, let’s talk more about how your organization can increase yours (and the benefits that it brings).

One of the simplest solutions to achieving efficiency with reporting procedures is compartmentalization. By singling out individual aspects of processes, we can ascertain more efficient stages to those protocols. However, we must also be able to view the process in the macroscopic form if we are to achieve objectivity about the nature of the process.

But what are the benefits of such an exercise? There’s actually more than you might expect.

Lower Risk With Better Inspections. Another benefit of prioritizing efficiency with your inspection reporting is the lowered risk. When you increase reporting efficiency, reports tend to become more precise. A directed approach always guides better than one lacking direction.

Inspection reporting is no different. The more concise, precise, and useable an inspection report is, the more efficient the delivery of vital information becomes. It lowers risk by lowering exposure to the risks of non-involvement.

Team Members Appreciate Organization. Most team members would agree that working for a disorganized management team is challenging at best. Increase your team’s overall morale merely by implementing more efficient systems. When you make your team member’s jobs a little easier, they will have more opportunities to do a better job.

We’ve looked at a few of the many benefits to improving your organization’s efficiency regarding inspections and the reporting process, but what about some actionable ideas you can take to implementation right now? Let’s see how we can help you to drive your organization even further forward with more efficient equipment inspections and report writing.

Inspect equipment as often as you can. Doing so will aid in the equipment maintaining a superior condition, and your inspection times will always decrease when equipment is kept in good working order.

Know all about the equipment that you need to inspect because then you can tell whether or not it’s working properly. It also makes the inspection process easier.

To make equipment inspection reporting more efficient, you can reverse engineer the equipment inspection process. By doing so, you can easily ascertain the critical elements of the inspection that require the most attention. This practice allows for more efficient time management during the equipment inspection.

Make sure your equipment is in good working order for the inspection by making sure it is clean and not broken. Better maintained equipment provides faster inspections due to a lack of notable failures.

In order to make equipment inspection reporting efficient, you should have equipment inspections shared by all staff. That means equipment will be inspected more often and by more team members.

When you have more eyes on something, you have more chances of finding an elusive failure prior to failing. In turn, this process keeps equipment more positively maintained, improving the efficiency of operations involving the equipment including equipment inspections.

In equipment inspections, we need to be careful. Not only is equipment often hazardous, but if team members are unaware of its workings, it’s possible that injury or incident might ensue.

In order to mitigate the risk, ensure team members are highly trained on the equipment they face day in, day out. It will lower your organization’s risk, increase safety and operational awareness, and also improve your reporting efficiency.

Maintaining what we like to call the inspection kit is critical to a proper data capture process. However, you might want to consider foregoing the old pen and paper and try implementing some mobile form automation technology instead. We’ll talk more about that with the last (and the best) tip on our list.

Even though the equipment is in good condition, it can always become dirty as a result of the surrounding environment. Managers need to perform equipment inspections even if equipment looks okay on the outside to make sure they do not overlook potential issues.

Managers need to perform regular equipment inspections and not let appearances fool them into thinking equipment is safe and clean. We know that dirt and debris can still accumulate quickly in some places, hiding wires, and other potential equipment problems.

Obtaining several opinions on the status of equipment being inspected will ensure equipment is in good working order to reduce the risk of injury or equipment damage. It also helps mitigate the potential for missed issues due to a lack of knowledge of specific equipment’s workings by the operator.

Unless equipment inspections are being done at the time equipment maintenance checks are being done, managers have to create an organization-wide system of regular equipment inspections that are also shared by all staff to obtain faster inspections with better results.

Mobile apps for business reporting can help you to automate your data capture process and maximize efficiency for checking maintenance logs, adding additional notes during an inspection, finalizing records without tedium, and much more!

The organizations using 1st Reporting‘s software are loving the built-in template library and the customizable template features. Not to mention that they also love the customizable notifications – so you could have the right people notified at the right time by the right report being completed.

Sharing documents and retrieving documents has never been easier with ultra-fast cloud-based technology. Not only is it easily accessible to those you appoint the privilege, but it’s also ultra-secure. So you know your organization’s data is kept safe and sound.

By following these steps you can have an efficient equipment inspections process in no time at all! Get started today with our free downloadable equipment inspection form by clicking here to learn more about how 1st Reporting‘s mobile form automation solutions can benefit your company.